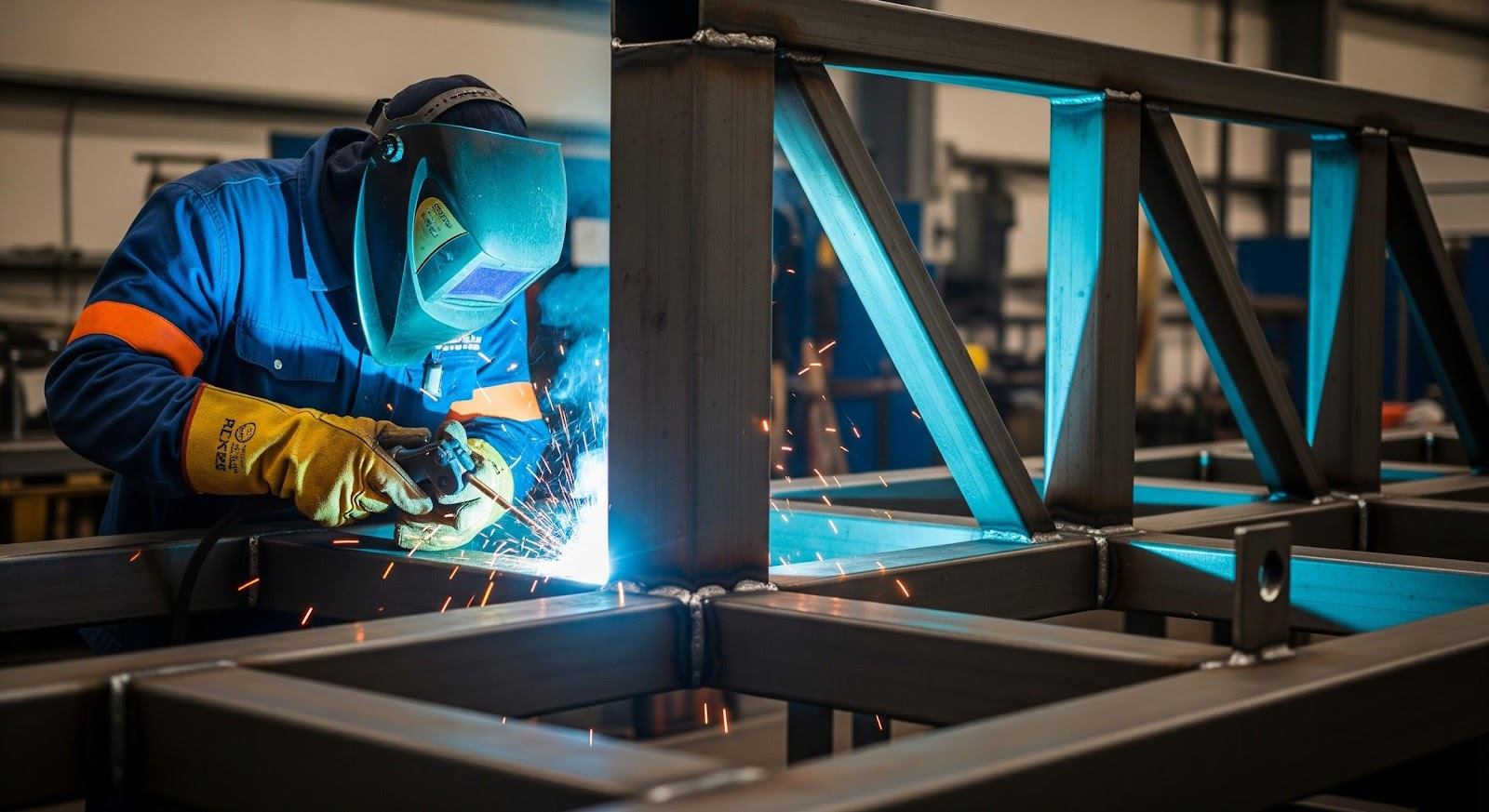

Welding is one of those trades that touches almost every industry in Canada. Right from construction to car repairs, from aerospace to manufacturing, welded components make it all strong and trustworthy. But if one gets welding services outsourced, then the price is diverse. Business owners, contractors, and even homeowners typically wonder why the same kind of job might be charged differently in one location compared to another. The reality is that numerous factors are involved when it comes to prices. Knowing them can assist you in making realistic assumptions and performing your projects better.

Table of Contents

Type of Welding Process

The initial factor that impacts the cost is the kind of welding that is being done. Every process is of various sophistication and needs various equipment. MIG welding is simple and not that sophisticated, so it is one of the cheaper processes. TIG welding takes more time, is skill-oriented, and is more delicate, particularly for thinner material or elaborate design, so it will cost more. Stick welding, which is used in construction and heavy industry, will be somewhere in the middle. If the project involves sophisticated techniques such as laser welding or robotic welding, obviously it will be more expensive because of the technology involved.

Materials Being Welded

All metals are not equal when welding. Mild steel is the cheapest because it is the easiest to weld and the most common. Aluminum and stainless steel involve higher skills and special equipment, therefore, they are more costly. Exotic metals for aerospace or medical uses can drive the cost even higher. Finally, material thickness is also a concern. Heavy metals are more heat and time to work with, and extremely thin material is extra special care not to warp. Both of those can contribute to total cost.

Labour and Skill Level

Welding is a trade, and how much experience the welder has is well worth a portion of the expense. An experienced welder with a great deal of skill, who is capable of making sharp, clean welds with minimum need for rework, will, of course, cost more than a less skilled one. Certified welders in Canada spend numerous years training and testing, and thus their work has value. The labor cost also varies with location. Welders in metropolitan areas such as Toronto or Vancouver will cost more than welders in small towns due to increased costs of living and service demand.

Project Size and Complexity

Project size directly determines the cost. Small repair jobs will only take an hour or two and are low cost. Mass production type jobs that involve hundreds of welds, precise blueprints, or specialty work might take a week or two. The more complicated the job, the longer and the more planning needed. A good example would be fixing a simple gate not costing nearly as much as repairing structural steel frames for a business complex. Complicatedness also includes accessibility of the space that needs welding. Narrow spaces, working above shoulder height, or poor postures tend to decelerate the process and add labour hours.

Equipment and Technology

Equipment type will also impact cost. It is cheaper to power lower-end welding equipment, but higher-end equipment such as CNC plasma cutters or robotic welders are very costly to purchase and maintain. Companies that do invest will charge you too much, but they will deliver you with faster turnaround and very accurate results. If specialized equipment is needed to perform your work, you’ll discover you pay more with the added capability.

Location and Travel Cost

Geography also has an impact on welding service cost. In the urban areas, welders can have convenient access to supplies, vendors, and a consistent customer base but high overhead costs, which drive prices up. Rural areas can offer low-priced services, but in the event that a lot of traveling is required to get to your location, traveling charges can be added. Mobile welding is convenient, but the transportation cost of heavy machinery and gas is most likely included in the end.

Preparation and Finishing Work

It is seldom a one-step operation. Most operations involve pre-weld processing. Weld metal preparation, rust removal from the metal, or measuring up the components contribute to the time factor. Then, following the weld, there could be post-weld treatments such as grinding, polishing, or painting, depending upon application. Each one contributes labour and thus expenses. Customers usually do not know these considerations, but they are part of the overall price calculation.

Safety and Compliance

Welding positions in Canada usually must comply with stringent safety codes and regulations, particularly in sectors such as construction, oil and gas, and transportation. Compliance in such cases might involve tests, certificates, and certain safety gear. Although the conditions guarantee quality and safety for employees, they do contribute to the overall price. Businesses that comply with high safety standards might be more expensive, yet the dependability and legality they offer are completely worthwhile.

Supply Chain and Market Conditions

Like in most industries, welding is susceptible to demand and supply. Steel prices have a direct impact on material prices as well as weld prices, with higher steel prices leading to both escalating. Shortage of qualified welders in some areas also contributes to increasing the cost of labour. During times of peak demand, like when there are big construction projects or periods of building booms, prices will be higher than during times of less demanding demand. On the other hand, when there’s low demand, you can expect improved pricing since welders will need to maintain steady work.

Getting the Best Value

Price is always a factor, but cheapest price is not necessarily the best. Poorly done welds cause structural failure, costly repairs, and loss of life. When getting estimates, do not only look at the bottom line. Request experience, certifications, and quality control procedures of the welder. It is also a good idea to iron out the scope of work in detail to avoid hidden charges later. Open communication allows both parties to understand what they will get and avoids surprises.

Final Thoughts

Canadian welding service prices hinge on numerous variables. Process type, materials, labor, size of the project, equipment, and location all bear weight. Add in prep work, safety regulations, and market conditions, and it is simple to understand why prices are not the same. Having an understanding of what drives these factors gives you more insight into what you are paying for and makes you a wiser consumer. No matter if you require a minor fix, an industrial level of work, or are searching for a welding service near me, understanding what creates costs will make the process easier and the end result more predictable.